Race to Innovate: ASML's Lithography Supremacy and the Future of AI Chips

In a quiet Dutch town near Eindhoven, one company stands at the epicenter of a technological revolution. ASML, renowned for its advanced lithography machines, now finds itself in the middle of a global race that will determine the future of artificial intelligence, computing, and chip manufacturing.

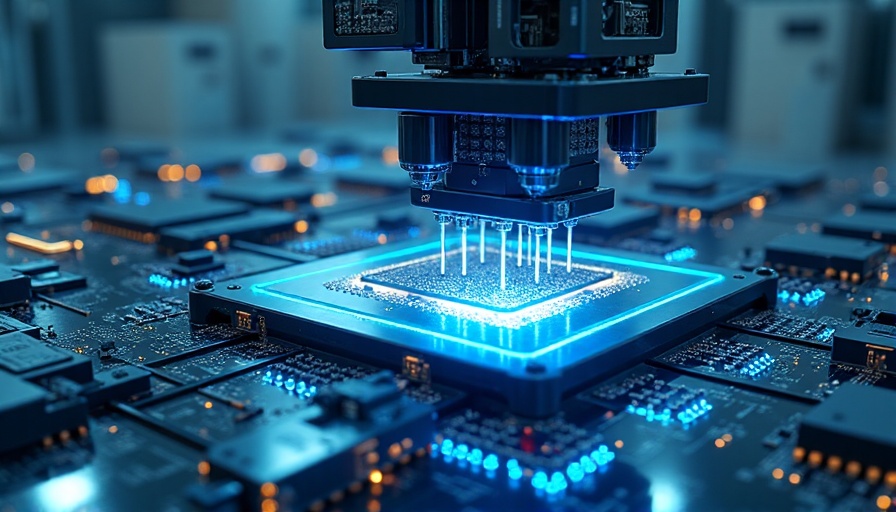

The Heart of High-Tech Chipmaking

At ASML's headquarters, engineers work on colossal machines that make ultra-precise AI chips. The latest of these, weighing 150 tonnes and costing about US$350 million, is the most advanced available. This machine uses an ingenious process where 50,000 droplets of molten tin are hit twice by lasers — first softening them into pancakes and then vaporizing them into hot plasma that reaches nearly 220,000°C. This extreme process generates extreme ultraviolet (EUV) light used to etch intricate patterns on silicon wafers.

Such patterns create the tiny circuits and intricate layers found in everything from AI accelerators to smartphones. With each chip containing billions of transistors and multiple layers of wiring, ASML's technology is indispensable. Companies like TSMC, Samsung, and Intel heavily depend on these machines to push the boundaries of modern semiconductor design.

A Technology Battle on the Global Stage

ASML’s sophisticated machinery has positioned the company at the center of a fierce global technological contest:

- U.S.-China Tensions: To curb China's ability to manufacture advanced AI chips, the U.S. government has imposed restrictions on the sale of ASML’s most cutting-edge equipment to Chinese companies. In retaliation, China is investing billions in developing domestic alternatives.

- Rival Innovations: Japanese company Canon is developing competing technology using nanoimprint lithography (NIL). This technique directly stamps circuit patterns onto wafers, offering a potentially cheaper alternative, though it faces challenges in defect management, alignment, and throughput.

The race is not merely about technological prowess but also strategic supremacy. ASML’s dominance is reinforced by decades of research, such as the evolution from deep ultraviolet (DUV) systems to the current high-NA EUV tools, and plans for a future hyper-NA machine that could further miniaturize chip features.

The Science of Lithography

ASML's machines are marvels of modern engineering. They rely on two key factors to achieve the extreme precision necessary for advanced chipmaking:

- Light Wavelength: By using EUV light with wavelengths around 13.5nm (compared to the 38nm possible with older systems), the machines are capable of printing features as small as 8nm on silicon wafers.

- Numerical Aperture (NA): The ability of mirrors to collect and focus light plays a critical role. By pushing from older NA values to a current 0.55 and exploring hyper-NA (above 0.75), ASML is constantly refining its ability to deliver exceptional precision.

The intricate process involves reflecting light with mirrors polished to trillionths of a metre, projecting chip circuits with the clarity of a slide projector. However, increasing precision leads to bigger, heavier components and higher power consumption, while costs soar with each technological leap.

Challenges and Competitors

ASML's rivals face significant hurdles:

- China’s Multi-Patterning Approach: With restricted access to ASML's latest tools, Chinese manufacturers are re-engineering older ASML machines through multi-patterning techniques, though this method adds complexity and reduces production speed.

- Canonical Competition: Canon's NIL approach, which works like a printing press to stamp patterns onto a wafer, promises lower costs but currently lags in throughput. Despite its potential for memory-chip production and other applications, NIL must overcome issues of defect control and alignment precision to compete on an industrial scale.

Future Implications

The developments in lithography are not just about making smaller chips; they have far-reaching implications for AI and computing. Whether ASML remains at the pinnacle or a new era of hyper-NA systems or alternative technologies emerges, the global race for technological superiority continues to shape the future. As breakthroughs unfold, AI models will benefit from faster, more energy-efficient chips, potentially transforming industries worldwide.

ASML's story is one of relentless innovation and strategic importance—a reminder that sometimes, the quietest corners of the world can yield the most groundbreaking technologies.

Note: This publication was rewritten using AI. The content was based on the original source linked above.